About

Metalform Industries, Inc.

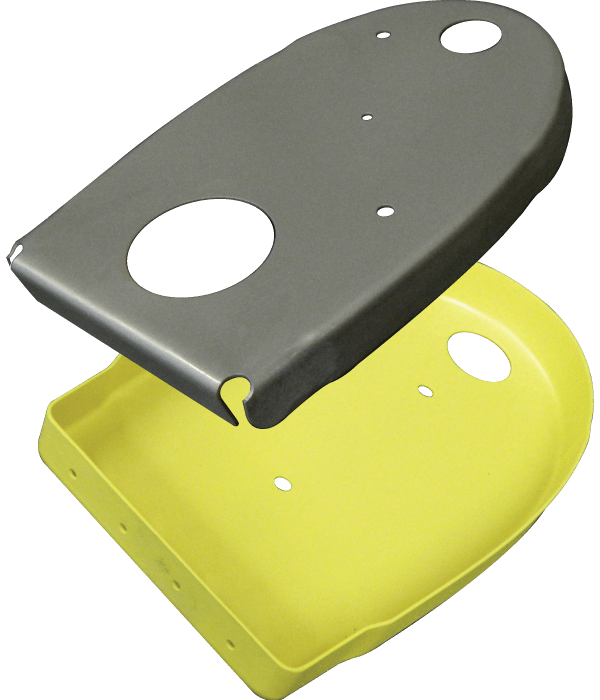

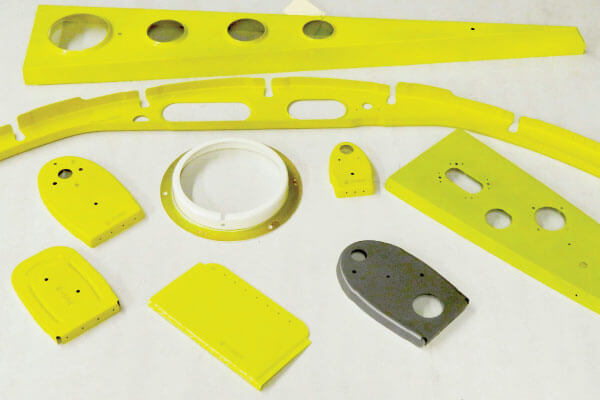

Metalform Industries, Inc. is an AS9100 certified company who has been in business since 1989 building superior quality, precision sheet metal parts and assemblies from a variety of materials including aluminum, stainless steel, titanium, rubber and phenolic just to name a few. Our customers include original equipment manufacturers of aircraft and helicopters as well as non-OEM designers and manufacturers for commercial, military and business/regional jets as well as the automobile and agricultural industries. Representative companies through the years include, Avcorp, Bell, Boeing, Case, Cessna, Commander, Fokker, Kaman, Nordam, Senior, Spirit, Tiger, Triumph, UTC and WSCO just to name a few. Our goal has always been, to use our precision manufacturing capabilities to better satisfy the needs of our customers by continually improving our effectiveness in delivering a defect free product to them, on time, every time, at the best price possible. Over the past 25 years, we have partnered with and supply our customers a variety of items from existing customer tooling or if needed we can build tooling to meet our customers’ needs.

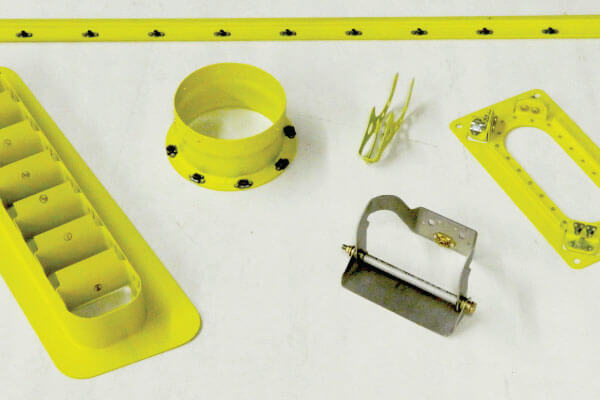

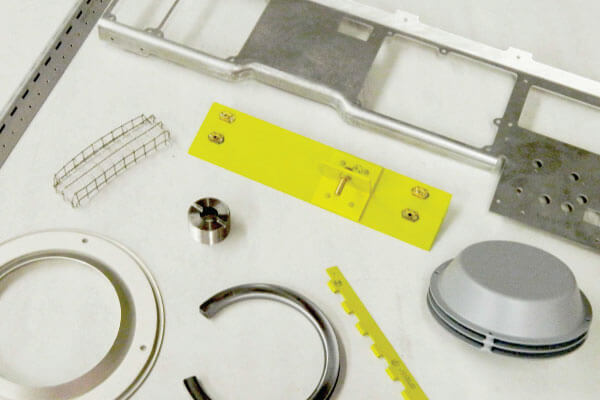

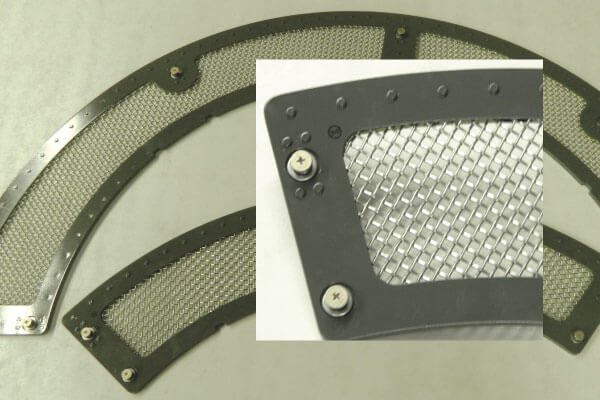

Some single components we manufacture include but are not limited to: anchors, angles, arms, caps, channels, clamps, clips, cushions, doors, doublers, drain tubes, drip pans, fillers, formers, frames, gaskets, guards, gussets, handles, hinges, ice boxes, louvres, pans, panels, plates, plugs, popcan racks, ribs, screens, shields, shims, skins, spacers, spars, springs, step mats, strikers, strips, supports, tabs, tank tops, tees, tracks, trash bins, tubes, webs and zees.

In house assembly includes riveting and room temperature bonding (not requiring autoclave or clean room requirements). Assemblies can be as easy as installing nutplates to complete assemblies of items like Air Duct Assemblies for helicopters to Torque Tube Assemblies for aircraft flight controls.

THANK YOU FOR FINDING US. PLEASE FEEL FREE TO LOOK AROUND AND CALL WITH ANY QUESTIONS YOU MIGHT HAVE REGARDING OUR COMPANY OR YOUR OUTSIDE PRODUCTION NEEDS!!!